When it comes to plastic welding, surface preparation is often a necessary step to ensure a strong bond. However, Emabond welding breaks the mold by offering a technology that eliminates the need for surface preparation before welding. Let’s explore why Emabond welding stands out from other welding methods and why skipping surface prep can save time and resources.

The Advantages of Emabond Welding Over Traditional Methods

1. No Surface Preparation Required

Traditional welding techniques, such as hot plate welding, ultrasonic welding, or adhesive bonding, often require surface cleaning and preparation to ensure a good weld. Surface contaminants like dust, grease, or oxidation can weaken the bond and lead to poor weld quality. However, Emabond welding’s electromagnetic heating is highly efficient and generates heat directly within the material. This localized heating ensures that surface contaminants do not significantly affect the weld quality, making surface preparation unnecessary.

2. Time and Cost Savings

Skipping the surface preparation step can dramatically reduce production time and labor costs. In many industries, cleaning and preparing surfaces before welding is a time-consuming task that requires specialized equipment and chemicals. By eliminating this step, Emabond welding can streamline the production process, allowing for faster throughput and lower overall costs.

3. Improved Weld Quality

Emabond welding offers consistent, high-quality welds because the process is less sensitive to surface conditions. The electromagnetic heating used in Emabond welding penetrates deep into the material, ensuring a uniform weld throughout. This contrasts with other methods, where uneven surface conditions can lead to inconsistent bonding and weaker welds.

Why Do Other Welding Techniques Require Surface Preparation?

The need for surface preparation in traditional welding methods is largely due to the nature of heat transfer and bonding. Here’s why:

- Hot Plate Welding: This method relies on direct contact between the heated tool and the plastic surface, making it crucial for the surfaces to be clean and smooth for optimal heat transfer.

- Ultrasonic Welding: In ultrasonic welding, high-frequency vibrations generate heat at the joint interface. Surface contaminants can interfere with these vibrations and disrupt the bonding process.

- Adhesive Bonding: Adhesives require clean surfaces for the glue to adhere properly. Any contamination can compromise the bond’s integrity, leading to a weaker weld.

How Emabond Welding Changes the Game

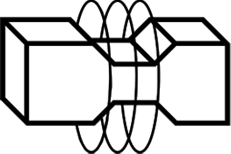

The key to Emabond welding’s ability to bypass surface preparation lies in its use of electromagnetic energy and susceptors. The susceptors, typically metal or conductive material, absorb the electromagnetic energy and convert it into heat. This heat is generated internally within the joint area, rather than being applied externally. Because the heat generation occurs inside the material, it is less affected by any surface contaminants.

Moreover, the process is designed to create a robust weld that can withstand harsh conditions. This makes it suitable for demanding applications where reliability is crucial, such as in automotive parts or medical devices.

Conclusion

Emabond welding offers a significant advantage over traditional welding techniques by eliminating the need for surface preparation. With its time-saving and cost-effective approach, this technology is setting new standards in the welding industry. If you’re looking for a welding solution that provides consistent, high-quality results without the hassle of surface prep, Emabond welding is the way to go.

By understanding why Emabond welding doesn’t require surface preparation, industries can better appreciate its benefits and potential for improving manufacturing processes.