No, a distinct advantage of the Emabond process is that no pre-treatment is required. Read More:

FAQ

Yes, parts filled as high as 40% with various fillers are welded every day utilizing our technology. Read More:

Yes, although there is a variety of polyamides each with their own challenges based upon their steep melt curve, our technology is utilized on not just nylons but all kinds of engineered polymers. Read More:

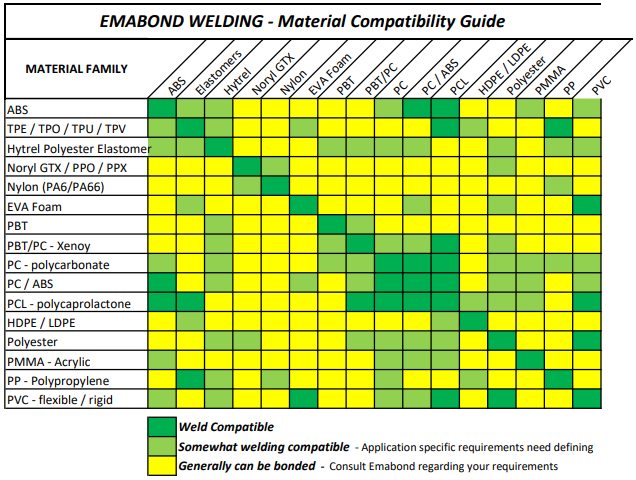

All thermoplastics can be welded; furthermore, the Emabond process also allows dissimilar materials to be welded as well. See the compatibility chart on our website to find the materials used on your application. Read More:

While this is dependent on your product specifications and requirements, the tongue and groove joint design shown on our home page is a great place to start.

Cycle times vary based on part size, shape, and thickness. For reference, the Emabond technology is comparable to other plastic processing methods.

No, precise heat at the bond-line is another major advantage when using the Emabond process. There is no radiant heat and the tooling remains at ambient temperature throughout the welding cycle.

Yes, Emabond is a turnkey solutions provider. We can either automate the system ourselves or work with your automation company to deliver a successful launch into production.

Yes, an advantage of our technology is that we can formulate specialty materials that share attributes of both materials being welded.

Yes, 3D complex shapes are easily welded in our custom tooling. Read more:

No, the welded part comes out of the weld tooling exceeding your specifications.

Large parts can be welded using the Emabond technology. In some cases, multiple match/generators will run simultaneously to reduce cycle time for these large assemblies allowing parts of unlimited size to be welded.